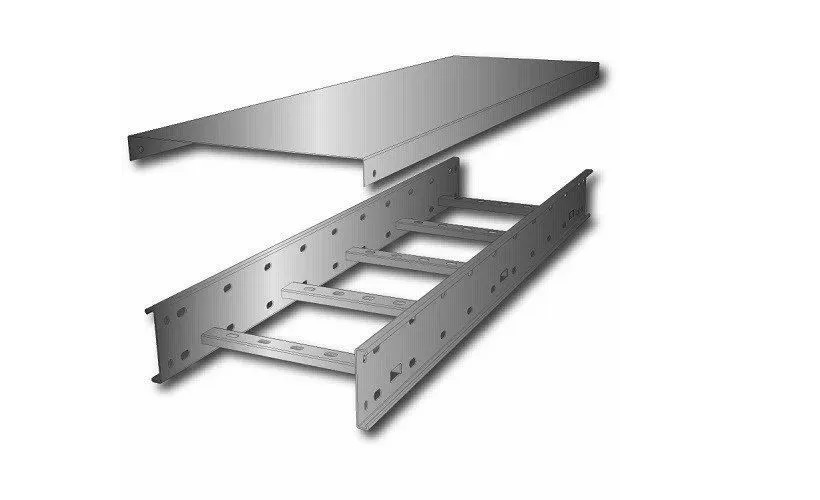

METAR Brand cable ladders are robust and versatile components designed for efficient cable management in various industrial and commercial applications. These ladders are engineered to support heavy loads and provide a secure pathway for cables, offering durability, reliability, and ease of installation. Here are the key features and functionalities of METAR Brand cable ladders:

Here are the key features and functionalities of METAR Brand cable ladders:

In summary, METAR Brand cable ladders exemplify durability, reliability, and versatility in managing cables across various industrial and commercial environments. Their robust construction, customizable configurations, and ease of installation make them a preferred choice for ensuring efficient and organized cable management in complex infrastructure projects.

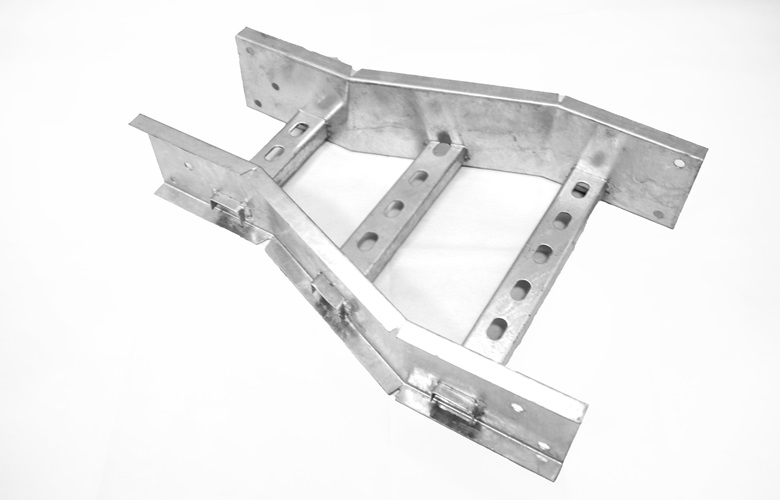

Here are the key features and functionalities of the 90-degree bend accessory for METAR Brand cable ladders:

In summary, the 90-degree bend accessory for METAR Brand cable ladders exemplifies functionality, durability, and efficiency in optimizing cable routing and organization within industrial and commercial environments. It enhances the versatility of METAR cable ladder systems, allowing for flexible configurations that meet specific project requirements while ensuring reliable and safe operation of electrical and data infrastructure.

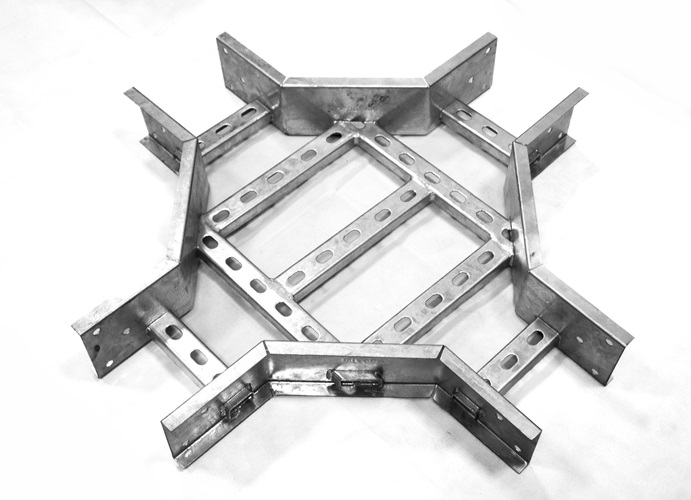

Here are the key features and functionalities of the Cross for METAR Brand cable ladders:

In summary, the Cross accessory for METAR Brand cable ladders exemplifies functionality, durability, and efficiency in optimizing cable routing and organization within industrial and commercial environments. It plays a critical role in ensuring seamless cable transitions, maintaining structural integrity, and supporting reliable operation of electrical and data infrastructure systems.

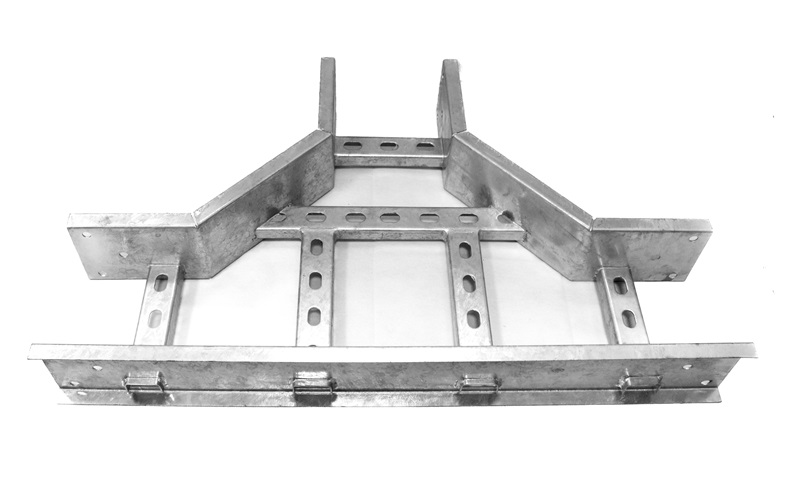

Here are the key features and functionalities of the TEE for METAR Brand cable ladders:

In summary, the TEE accessory for METAR Brand cable ladders exemplifies functionality, durability, and efficiency in optimizing cable distribution and organization within industrial and commercial environments. It plays a critical role in enhancing cable management flexibility, maintaining structural integrity, and supporting reliable operation of electrical and data infrastructure systems.

Here are the key features and functionalities of the Riser for METAR Brand cable trays:

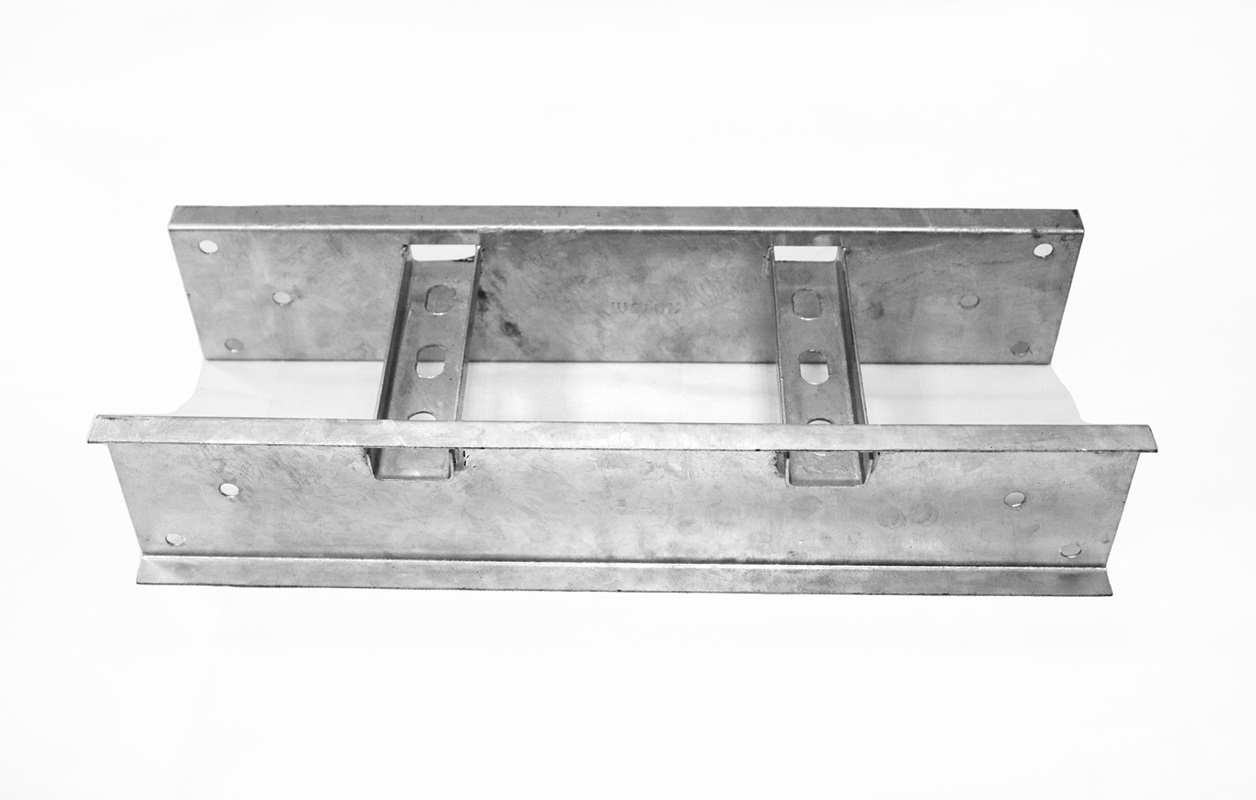

Here are the key features and functionalities of the Reducer for METAR Brand cable ladders:

In summary, the Reducer for METAR Brand cable ladders exemplifies functionality, durability, and efficiency in managing size transitions and optimizing cable routing within electrical and data infrastructure. It plays a critical role in maintaining seamless cable continuity, organizational efficiency, and structural integrity, contributing to reliable cable management in diverse industrial and commercial environments.

Here are the key features and functionalities of the cover for METAR Brand cable ladders:

In summary, the cover for METAR Brand cable ladders exemplifies functionality, durability, and efficiency in protecting and organizing cables within electrical and data infrastructure. It plays a crucial role in safeguarding cables from external elements, enhancing safety, and ensuring accessibility for maintenance and inspections, thereby contributing to reliable and efficient cable management in diverse industrial and commercial applications.

ANSWERS TO COMMON QUESTIONS

A cable ladder is a type of cable tray consisting of two longitudinal side rails connected by individual transverse rungs. It is used to support and route cables, providing easy access for installation and maintenance.

Cable ladders are commonly made from:

Installation involves:

1209, IT Plaza,

Dubai Silicon Oasis, Dubai, UAE