METAR Brand cable trays are recognized for their robust design and reliable performance in electrical and data management systems. These trays are engineered with a focus on durability, ease of installation, and versatility to meet the demanding requirements of modern infrastructure projects.

Here are some features and aspects that characterize METAR Brand cable trays:

METAR Brand cable trays are trusted solutions in the field of electrical infrastructure, offering robust construction, reliable performance, and versatility to meet the rigorous demands of modern electrical and data management systems. Their design and features contribute to efficient cable routing, safety compliance, and long-term operational reliability in various industrial and commercial applications.

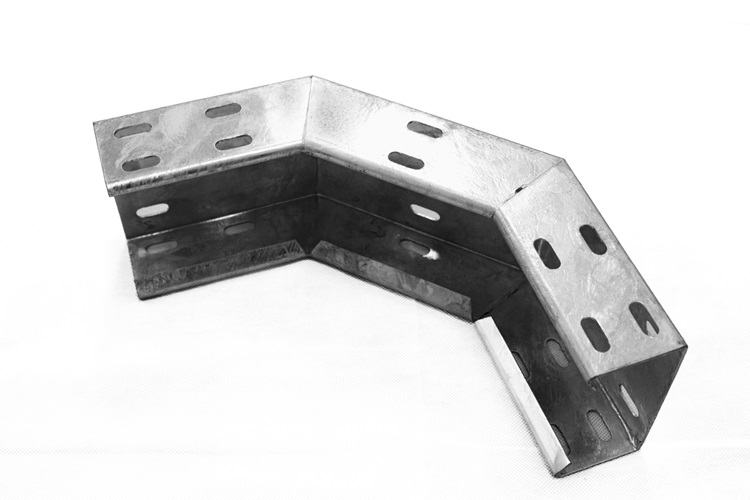

Key features and considerations regarding the 90-degree bends in METAR Brand cable trays include:

Overall, METAR Brand cable trays with 90-degree bends exemplify precision engineering and functionality in managing electrical and data cables. They contribute to the reliability, efficiency, and organization of wiring systems, ensuring seamless operation and maintenance in diverse industrial and commercial environments.

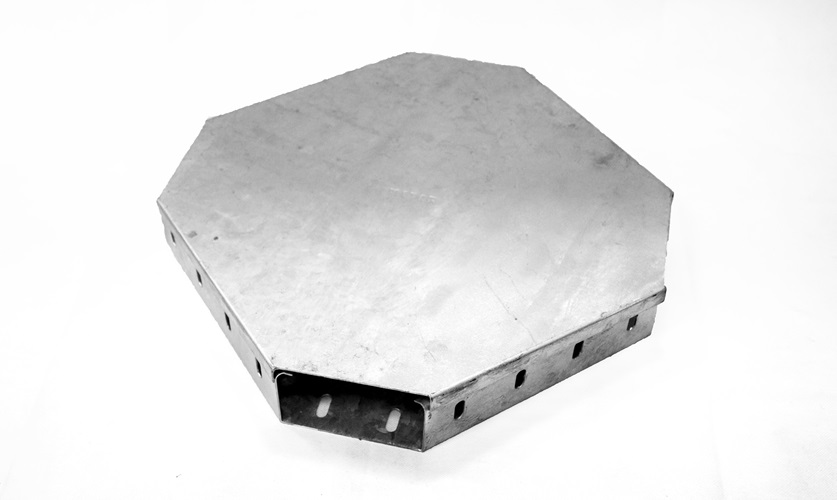

Here are the key aspects and functionalities of a cross in METAR Brand cable trays:

In summary, a cross in METAR Brand cable trays exemplifies precision engineering and functionality in managing the intersection of cables within electrical and data infrastructure. It contributes to efficient cable routing, organization, and space optimization while adhering to stringent safety and operational standards in diverse industrial and commercial environments.

Here are the key features and functionalities of the METAR Brand Tee for cable trays:

In summary, the METAR Brand Tee for cable trays exemplifies functionality, durability, and efficiency in managing cable distribution and branching within electrical and data infrastructure. It plays a critical role in optimizing space, maintaining organization, and ensuring reliable cable management in diverse industrial and commercial environments.

Here are the key features and functionalities of the Riser in METAR Brand cable trays:

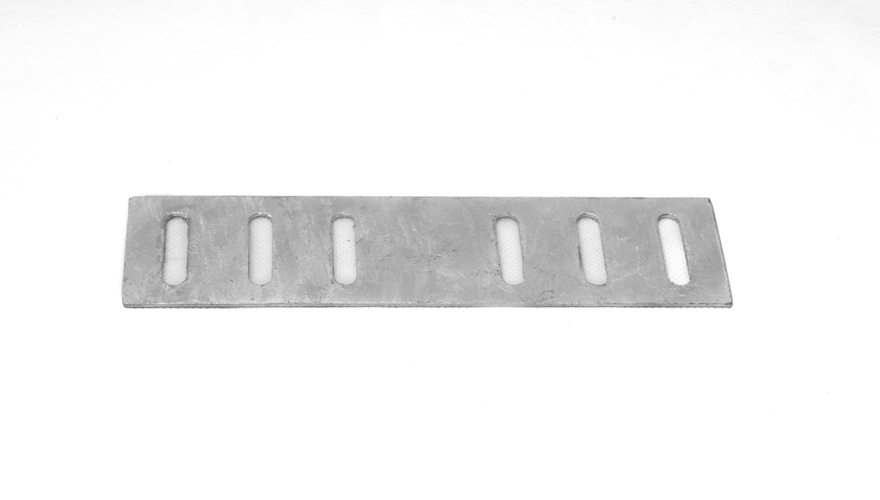

Here are the key features and functionalities of couplers in METAR Brand cable trays:

In summary, couplers in METAR Brand cable trays exemplify functionality, durability, and efficiency in extending and connecting cable tray sections within electrical and data infrastructure. They play a critical role in maintaining seamless cable routing, organization, and structural integrity, contributing to optimized space utilization and reliable cable management in diverse industrial and commercial environments.

Here are the key features and functionalities of Reducers in METAR Brand cable trays:

In summary, Reducers in METAR Brand cable trays exemplify functionality, durability, and efficiency in adapting cable tray sizes and capacities within electrical and data infrastructure. They play a critical role in maintaining seamless cable routing, organization, and structural integrity, contributing to optimized space utilization and reliable cable management in diverse industrial and commercial environments.

Here are the key features and functionalities of the METAR Brand cable tray cover:

In summary, the METAR Brand cable tray cover exemplifies functionality, durability, and efficiency in protecting and organizing cables within electrical and data infrastructure. It plays a critical role in safeguarding cables from damage while ensuring accessibility for maintenance and inspections, thereby contributing to safe and reliable operations in diverse industrial and commercial applications.

ANSWERS TO COMMON QUESTIONS

Cable trays are commonly made from:

When choosing a cable tray, consider:

Installation typically involves:

Can cable trays be used outdoors?

Maintenance involves:

Yes, cable trays can be used for both power and data cables, but it’s crucial to maintain proper separation to avoid interference, following applicable standards and regulations.

1209, IT Plaza,

Dubai Silicon Oasis, Dubai, UAE