METAR brand lintels and brackets are crucial components in construction, offering robust solutions for supporting masonry openings, windows, doors, and other structural elements. Known for their durability and versatility, METAR lintels and brackets are designed to withstand heavy loads and provide long-lasting support in residential, commercial, and industrial applications.

In conclusion, METAR lintels and brackets are integral components in modern construction, offering robust support solutions that enhance structural integrity, durability, and efficiency. Whether supporting masonry openings or securing structural elements, METAR products are trusted for their quality craftsmanship and performance in diverse building environments.

ANSWERS TO COMMON QUESTIONS

A steel lintel is a horizontal support beam made from steel, used in construction to span openings such as doors, windows, and other architectural features. It helps distribute the weight of the structure above the opening.

Steel lintels are commonly used in masonry construction, including brick and stone buildings, to support the loads over door and window openings, and in other areas where openings need to be created in walls.

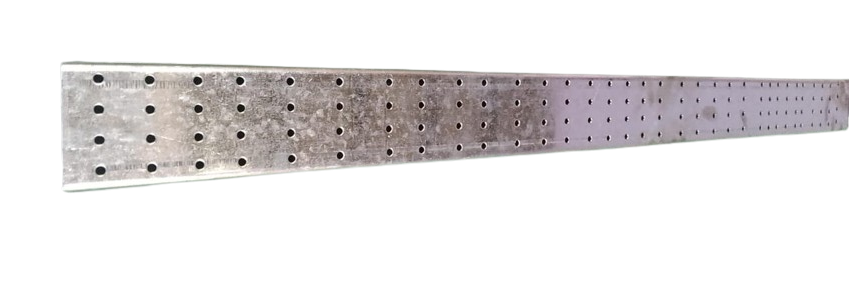

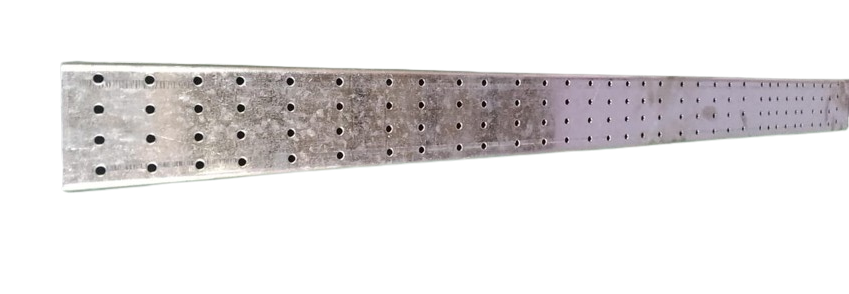

Steel lintels come in various shapes and sizes, including angle lintels, T-section lintels, and box lintels. The choice depends on the load requirements and specific application.

Steel lintels are typically made from galvanized or stainless steel to prevent corrosion and ensure durability. They may also be coated or painted for additional protection.

Installing a steel lintel involves placing the lintel across the opening and ensuring it is level. It should extend sufficiently into the adjacent walls to bear the load. Mortar or other bonding materials are used to secure it in place.

The bearing length is the portion of the lintel that rests on the supporting wall. It typically needs to be at least 150 mm (6 inches) on each side of the opening, but this can vary based on the load and local building codes.

Yes, steel lintels can be cut to the required size using appropriate cutting tools such as a saw or grinder. Ensure to treat any cut edges to prevent rust and maintain structural integrity.

The load-bearing capacity of a steel lintel depends on its size, shape, material, and the span of the opening. Refer to manufacturer specifications and engineering guidelines for exact load capacities.

In some cases, steel lintels may need to be reinforced, especially for large spans or heavy loads. Reinforcement methods can include additional steel plates or combining with other structural elements.

Regular inspections should be conducted to check for any signs of corrosion, deformation, or damage. Ensure that any protective coatings are intact and repair or replace lintels showing significant wear.

Yes, steel lintels are highly durable, especially when made from galvanized or stainless steel. They are resistant to rust, decay, and can withstand significant structural loads.

Yes, cable trays can be used for both power and data cables, but it’s crucial to maintain proper separation to avoid interference, following applicable standards and regulations.

Yes, steel lintels are safe when installed correctly and according to building codes and manufacturer guidelines. They provide robust support for masonry and other structures.

Signs of a failing steel lintel include visible sagging, cracks in the masonry above the lintel, rusting or corrosion, and separation from the supporting walls. Immediate inspection and repair are required if these signs are observed.

Yes, steel lintels are designed to comply with various industry standards such as ASTM, BS (British Standards), and local building codes. Always check the specific product for compliance certifications.

Regulations can vary by region and application. Ensure that the installation of steel lintels complies with local building codes, construction standards, and engineering practices.

Consider factors such as the load requirements, span of the opening, environmental conditions, and the type of construction. Consulting with a structural engineer or supplier can help you select the appropriate lintel.

Steel lintels can be purchased from building supply stores, steel fabricators, construction material suppliers, and online retailers. Ensure you buy from reputable sources to get quality products.

The cost of a steel lintel varies based on its size, shape, material, and any additional coatings or treatments. Contact suppliers for specific pricing and quotes.

Yes, steel lintels can be customized to specific lengths, shapes, and coatings to meet unique project requirements. Consult with the manufacturer or supplier for customization options.

In coastal or corrosive environments, it’s important to use stainless steel or galvanized steel lintels with additional protective coatings to prevent rust and corrosion. Regular maintenance and inspections are also critical in these conditions.

Yes, many suppliers and manufacturers offer technical support and guidance for installing steel lintels. Consulting with a structural engineer can also provide additional support and ensure proper installation.

1209, IT Plaza,

Dubai Silicon Oasis, Dubai, UAE