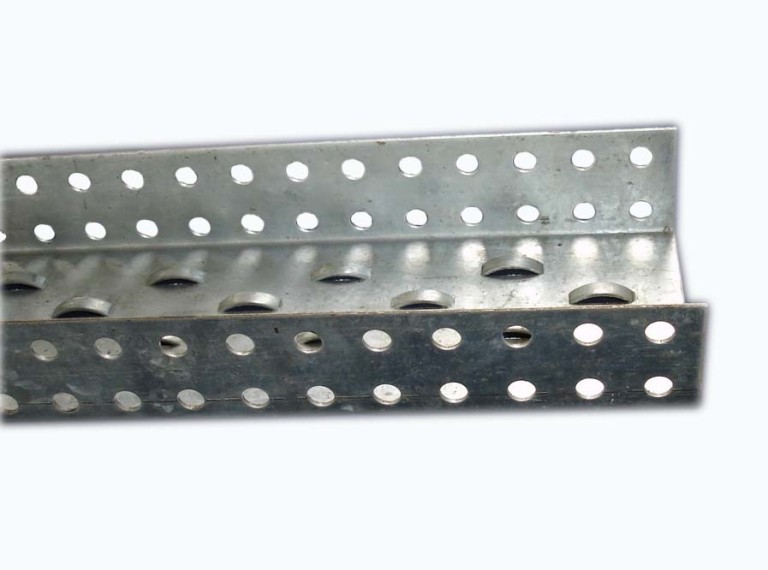

Manufactures and produced under the guidelines of BS 4678 part-1, the cable trunking has been introduced to provide a system to make sure that the wiring system is managed properly and laid out without any form of mix-up. This type of trunking system was brought up to make sure that various clients were provided with the wiring at the same time instead of delivering to them individually. To put in simple terms, a trunk is simply a transmission channel between two different wires and either of these acts as the node or the switch point for the entire wiring.

Specifications of the GI trunking, UAE

As per the specifications of the BS EN 10142, the pre galvanized steel or the hot dip galvanized steel is used in the fabrication of the GI pipes. In order to provide colours to the trunking system, epoxy polyester powder coating is provided in order to match with nay of the RAL colours. An aluminium cable tray is fit to the trunking system for the cables to rest upon. These GI pipes are also available in the screw type stainless steel trunking system.

Apart from these, the general specifications of the GI trunking, UAE, include the use of turnbuckles that help in fixing the lid for the trunking system. In order to ensure that the cables are provided with a smooth place for turns, the cable trunking, UAE, has provided the entire trunking set up with a gusseted construction and also an integral coupler. It is made sure that all the pieces that are being manufactured and produced are state of the art and does not have any kind of defect.

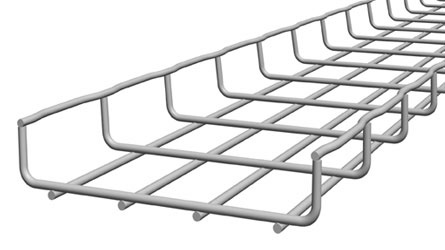

Types of cable trunking

The market has various types of trunking systems for the cables to ensure that no place faces the problem with the messy cables. Also, the trunking of the cables have reduced the time spent on giving out connections to the different clients from the one single line of wire. Creating a hub ensures that, the time that is spent on installing separate cables and the money that is spent are reduced. Generally, these trunking systems for the GI pipes are available as the 90-degree bend, 45-degree bend, and the Tee trunks. Apart from these, the types are,

Weather proof:

This is useful in protecting the cable from dust and water. These have an outward flange design and are fitted with gaskets to ensure that there is tight sealing.

Raised floor:

These are manufactured to produce a high degree of flexibility to the whole setup.

Service outlet:

This comes in handy when 3 or 4 compartments are needed to fit the cables.

FAQs:

FAQs about Cable Trunking

Cable trunking is a system used to protect, route, and manage electrical cables within buildings or structures. It consists of a rigid, enclosed channel that keeps cables organized and secure.

- Protection: Shields cables from physical damage, dust, and moisture.

- Organization: Keeps cables neatly organized and prevents tangling.

- Aesthetic Appeal: Provides a tidy appearance by concealing cables.

- Safety: Reduces the risk of electrical hazards by keeping cables enclosed.

Cable trunking is typically made from:

- Plastic (PVC): Lightweight, cost-effective, and easy to install.

- Steel: Durable and provides excellent mechanical protection.

- Aluminum: Lightweight and resistant to corrosion.

- Stainless Steel: Ideal for high-corrosion environments and industrial applications.

- Standard Trunking: Basic enclosed channels for general use.

- Mini Trunking: Smaller in size, ideal for domestic or small office applications.

- PVC Trunking: Common in residential and commercial installations due to its flexibility and ease of installation.

- Metal Trunking: Used in industrial settings for enhanced protection.

- Perforated Trunking: Has holes for ventilation, preventing overheating of cables.

Installation involves:

- Planning the Route: Determining the path for the trunking.

- Measuring and Cutting: Cutting the trunking to the required lengths.

- Fixing the Trunking: Mounting the trunking to walls, floors, or ceilings using screws or adhesive.

- Laying the Cables: Placing the cables inside the trunking.

- Securing the Covers: Attaching the covers to enclose the cables.

- Cable Capacity: Ensuring the trunking size can accommodate the number of cables.

- Material: Choosing a material suitable for the installation environment.

- Fire Resistance: Selecting fire-resistant trunking if required by local regulations.

- Ease of Installation: Considering the ease of cutting, fixing, and modifying the trunking.

- Residential Buildings: For organizing and protecting electrical and communication cables.

- Commercial Buildings: To manage cables in offices, retail spaces, and public buildings.

- Industrial Facilities: For protecting cables in factories and warehouses.

- Data Centers: For organizing large volumes of data and power cables.

- Regular Inspections: Checking for physical damage, wear, and loose fittings.

- Cleaning: Keeping the trunking free from dust and debris.

- Updating Layouts: Modifying the system as cables are added or removed to ensure it remains organized and not overloaded.

- Replacing Damaged Sections: Promptly replacing any damaged parts of the trunking.

- NEC (National Electrical Code): Provides guidelines for the safe installation and use of cable trunking in the US.

- NEMA (National Electrical Manufacturers Association): Sets standards for the design and performance of cable trunking, ensuring safety and quality.

Yes, cable trunking can be used outdoors, but it should be made from materials that can withstand environmental factors such as UV radiation, moisture, and temperature changes. Weatherproof or UV-resistant trunking is recommended for outdoor use.

- Proper Installation: Ensuring the trunking is securely fixed and cables are properly enclosed.

- Load Limits: Not overloading the trunking with too many cables.

- Fire Safety: Using fire-resistant trunking in areas where fire risk is a concern.

- Secure Covers: Making sure the covers are securely fastened to prevent cables from being exposed.

Yes, cable trunking can be used for both power and data cables. However, proper separation should be maintained to avoid interference and comply with relevant electrical codes and standards.

Get a quotation for your desired products

Click HereOur Certification