Metar Strut Channel/ Metal Framing Systems

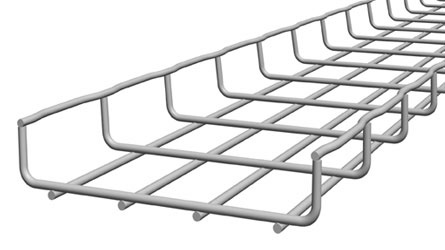

The metal framing systems serves as the beam or the support for the layout of the cable channels. The entire layout of the cables can be kept upon these frames that can withstand the load of the cable to make sure that these do not come in way. Lots of cable in the place can cause hindrance to the people walking by and mostly takes up half of the space. With the framing system, all these can be removed from the path of the person at the place, thus ensuring a safe environment for both the person and the cable layout.

Metal framing systems specifications:

Also called as the C channel, UAE or the U channel, UAE, these framing systems are manufactured and produced according to the standard specifications in the industry that confers to BS 6946. These frame systems comes in various specifications and are available in the market. All these are manufactured either in aluminium or in stainless steel.

The Strut Channel in UAE is seen in various types based upon the production type and the need that they serve in the places. The various types of these framing systems include,

-

1-5/8″ Strut Metal Framing Channel:

This type of C channel, UAE, comes in holes and slots type of framing channels. Also, these can also be availed welded back to back to each other.

-

1-1/4″ Strut Metal Framing Channel:

This framing type is small when compared to the previous metal framing system and mostly available welded back to back to each other. More than one piece of the framing can be stacked upon each other to create the layout.

-

13/16″ Strut Metal Framing Channel:

These are shorter in length than the previous two types of framing systems. Two or more of the frames are welded back to back or stacked upon each other to support the cable layout.

-

Strut 1-5/8 Metal Framing Strut Fittings:

The fittings for the U channel, UAE and the C channel, UAE are available to hold the framings in place when needed. This way, more than one type of framing can be fixed in the place for the support of the cable layout. Some of common fitting types include, flat fittings, angular fittings, wing fittings, beam clamps and trolleys.

-

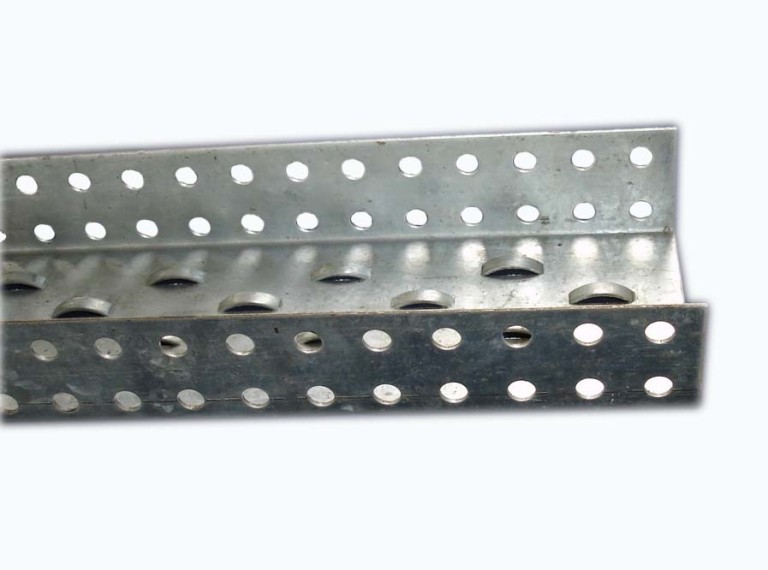

Strut Pierced and Slotted Channel:

The holes in the channel help to hold the other frames that need to be fit along with the existing ones with the help of a fitting. These are available in holes and slots combination and can also be purchased by welding them back to back to each other.

-

1-5/8 ” Strut Channel Strut Nuts With Springs:

The spring type of the channel nuts ensure that they are easy to be detached from the layout when they have to re-install at a different place.

FAQs:

General Information

A slotted channel, also known as a strut channel or strut, is a structural system used for supporting electrical, mechanical, and plumbing installations. It features a series of slots or holes along its length to allow for easy installation of components.

Slotted channels are used in a variety of applications including cable management, supporting HVAC systems, mounting electrical equipment, and in framing applications for construction projects.

Installation and Usage

Slotted channels can be installed using a range of fittings, brackets, and hardware. They are typically mounted to walls, ceilings, or floors, and components can be attached using bolts, nuts, and other fasteners designed to fit the slots.

Yes, slotted channels can be cut to the required size using appropriate cutting tools such as a hacksaw, bandsaw, or a cutoff saw. Ensure to deburr the edges after cutting.

Components can be attached using various fittings like spring nuts, bolts, and brackets that are designed to fit into the slots of the channel. These allow for adjustable and secure attachment of different items.

Materials and Durability

Slotted channels are commonly made from galvanized steel, stainless steel, aluminum, or fiberglass, depending on the requirements of the application and the environmental conditions.

Yes, slotted channels are designed to be durable and withstand significant loads. The material and finish determine their resistance to corrosion and wear, making them suitable for various environments.

Yes, slotted channels made from corrosion-resistant materials such as galvanized or stainless steel can be used in outdoor applications. Ensure the appropriate material and finish are selected based on environmental exposure.

Maintenance

Regular inspections should be conducted to check for any signs of wear, corrosion, or loose connections. Clean the channels periodically to remove dust and debris, and ensure all components are securely fastened.

Yes, slotted channels can be reused if they are in good condition. Ensure that the channels and all components are inspected for wear and compatibility with the new installation before reuse.

Safety

Yes, slotted channels are safe to use when installed and maintained correctly. They provide a robust and adjustable support system for various installations. Follow all safety guidelines and manufacturer instructions.

The weight limits for slotted channels vary based on the size, material, and manufacturer specifications. Always refer to the manufacturer’s guidelines and load tables to ensure the channels are not overloaded.

Standards and Compliance

Yes, slotted channels are designed to comply with various industry standards such as ASTM, DIN, and ISO. Always check the specific product for compliance certifications.

Regulations can vary by region and application. Ensure that the installation of slotted channels complies with local building codes, electrical codes, and industry standards.

Purchasing and Cost

Consider factors such as the load requirements, environmental conditions, size, and material. Consult with a supplier or manufacturer to select the appropriate channel and accessories.

Slotted channels can be purchased from hardware stores, electrical supply stores, online retailers, and directly from manufacturers. Ensure you buy from reputable sources to get quality products.

The cost varies based on the size, material, finish, and quantity of the channels, as well as any additional fittings and accessories required. Contact suppliers for specific pricing.

Get a quotation for your desired products

Click HereOur Certification