Lintels are generally defined as the horizontal structure that is placed across an opening in order to support the structure that is present right above it. This is very much similar to the arch or the beam that is present in the household. The lintels differ from these two structures for the simple fact that, the lintels have a simple and easy construction. One of the added advantage of the lintels in the structure is that, the ends of the structure is fixed on the masonry work of the existing structure and thus the weight gets easily distributed along the structure. The lintels are doing quite the rounds in the market with their high quality production and the standards that are being followed during their manufacture.

Specifications of the steel lintels

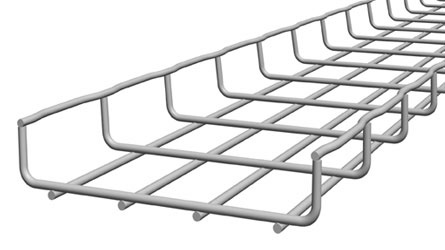

Steel lintels provides a better support to the structure than the others. They have high durability and resistance to heavy load. Steel lintels are being used at places where there is no proper support for the heavy loads. The ends of the lintels are embedded in the concrete that surrounds the structure and thus, these do not take up any kind of space. In order to place more than 2 units side by side, tube separators are used to enable the set up. People generally prefer to use more than 2 units during installation as these provide a better support for the steel joists.

The steel lintels consist of rolled steel joists and steel angles. The former is used for heavy loading purposes and the latter is used in case of light loads. During installation, these steel lintels are used either as a single unit or as a combination of 2 or 3 units. The presence of concrete for embedding the structure makes the lintels in UAE resistant to fire and also increases the durability of the structure. Along with the concrete, the steel lintels are considered to be the best support structure for the households and other places.

Types of steel lintels in UAE

-

Single wall lintels:

These are available as single units and can be fit on the wall as a whole.

-

Double wall lintels:

This is the combination of two single wall lintels welded back to back and thus, they provide better support to the structure than the single wall lintel.

-

Cavity wall lintels:

Some of the structures may have a small opening in them and these cavity wall lintels are manufactured to fit right into them so that the existing cavities do not cause any kind of harm to the entire house.

-

Arch and curved lintels:

Some of the archways at the place need extra support along with the arches and the beams that are present. These arch lintels are designed specifically for the arches and the curved out structures.

FAQs:

General Information

A steel lintel is a horizontal support beam made from steel, used in construction to span openings such as doors, windows, and other architectural features. It helps distribute the weight of the structure above the opening.

Steel lintels are commonly used in masonry construction, including brick and stone buildings, to support the loads over door and window openings, and in other areas where openings need to be created in walls.

ProcTypes and Materials

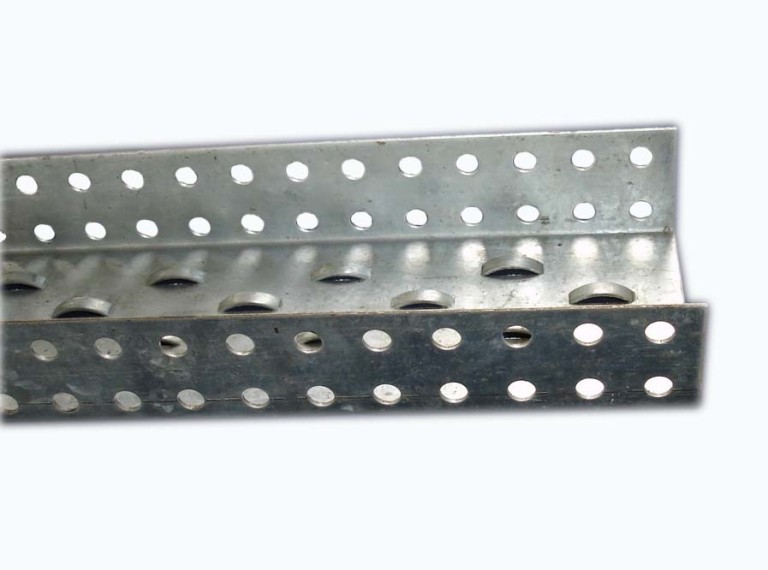

Steel lintels come in various shapes and sizes, including angle lintels, T-section lintels, and box lintels. The choice depends on the load requirements and specific application.

Steel lintels are typically made from galvanized or stainless steel to prevent corrosion and ensure durability. They may also be coated or painted for additional protection.

Installation and Usage

Installing a steel lintel involves placing the lintel across the opening and ensuring it is level. It should extend sufficiently into the adjacent walls to bear the load. Mortar or other bonding materials are used to secure it in place.

The bearing length is the portion of the lintel that rests on the supporting wall. It typically needs to be at least 150 mm (6 inches) on each side of the opening, but this can vary based on the load and local building codes.

Yes, steel lintels can be cut to the required size using appropriate cutting tools such as a saw or grinder. Ensure to treat any cut edges to prevent rust and maintain structural integrity.

Load and Structural Support

The load-bearing capacity of a steel lintel depends on its size, shape, material, and the span of the opening. Refer to manufacturer specifications and engineering guidelines for exact load capacities.

In some cases, steel lintels may need to be reinforced, especially for large spans or heavy loads. Reinforcement methods can include additional steel plates or combining with other structural elements.

Maintenance and Durability

Regular inspections should be conducted to check for any signs of corrosion, deformation, or damage. Ensure that any protective coatings are intact and repair or replace lintels showing significant wear.

Yes, steel lintels are highly durable, especially when made from galvanized or stainless steel. They are resistant to rust, decay, and can withstand significant structural loads.

Safety

Yes, steel lintels are safe when installed correctly and according to building codes and manufacturer guidelines. They provide robust support for masonry and other structures.

Signs of a failing steel lintel include visible sagging, cracks in the masonry above the lintel, rusting or corrosion, and separation from the supporting walls. Immediate inspection and repair are required if these signs are observed.

Standards and Compliance

Yes, steel lintels are designed to comply with various industry standards such as ASTM, BS (British Standards), and local building codes. Always check the specific product for compliance certifications.

Regulations can vary by region and application. Ensure that the installation of steel lintels complies with local building codes, construction standards, and engineering practices.

Purchasing and Cost

Consider factors such as the load requirements, span of the opening, environmental conditions, and the type of construction. Consulting with a structural engineer or supplier can help you select the appropriate lintel.

Steel lintels can be purchased from building supply stores, steel fabricators, construction material suppliers, and online retailers. Ensure you buy from reputable sources to get quality products.

The cost of a steel lintel varies based on its size, shape, material, and any additional coatings or treatments. Contact suppliers for specific pricing and quotes.

Customization and Special Considerations

Yes, steel lintels can be customized to specific lengths, shapes, and coatings to meet unique project requirements. Consult with the manufacturer or supplier for customization options.

In coastal or corrosive environments, it’s important to use stainless steel or galvanized steel lintels with additional protective coatings to prevent rust and corrosion. Regular maintenance and inspections are also critical in these conditions.

Technical Support

Yes, many suppliers and manufacturers offer technical support and guidance for installing steel lintels. Consulting with a structural engineer can also provide additional support and ensure proper installation.

Get a quotation for your desired products

Click HereOur Certification